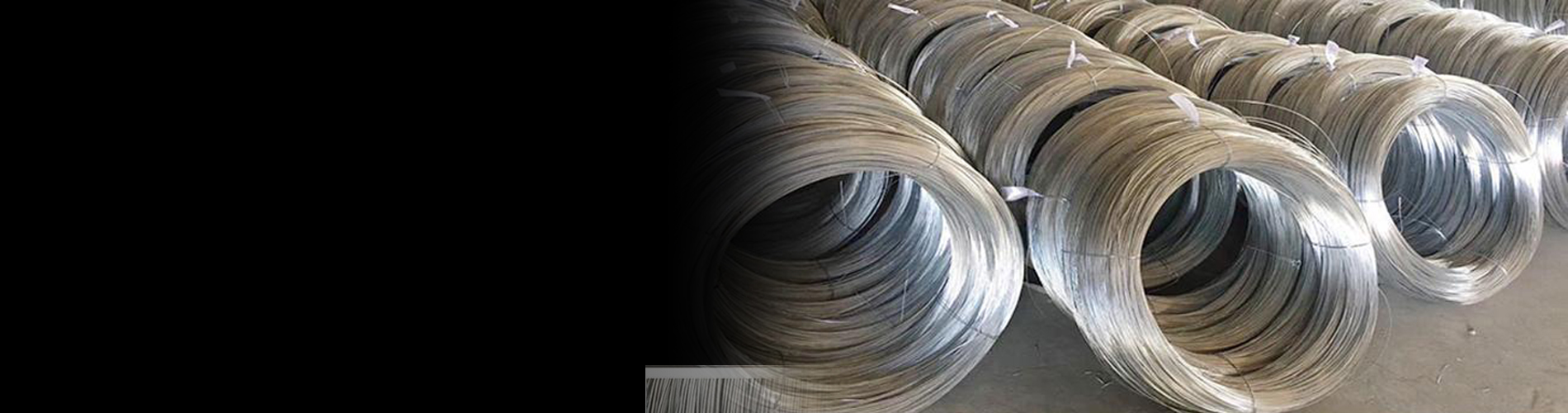

Our Steel Wire is manufactured in higher degree of accuracy. We are working in all possible verticals of commercial industries and are currently serving the wire needs of some significant industries like:-

Today Shree Laxmi Enterprises with the experience of more than 35 Years, is capable to manufacture Steel Wires in more than 25 Grades like SAE 1006, SAE 1008, SAE1010, SAE1015, SAE 1018, SAE 1022, high carbon grades like C35, C45, C50, C55, C60, C65, C70, C75 , C80, boron steel wires such as SAE 15B25, SAE 10B21, 19MnB4, SAE 15B41, and other alloy grades such as En 1A, En 8, En 8D, En 19, En 31, En 42, SCM 420, SAE 8620, SAE 1541, SAE 4140

All the above grades are available in different size ranges and packaging condition as per customer requirement

Specifications

| Grade | Chemical composition of various steel grades | |||||||||

| C% | Mn% | SI% | Cr% | Cu% | S% | P% | B% | Ni% | Mo% | |

| SAE 1006 | 0.08 Max | 0.35 Max | 0.10 Max | 0.050 Max | 0.040 Max | |||||

| SAE 1008 | 0.10 Max | 0.30-0.50 | 0.35 Max | 0.030 Max | 0.030 Max | |||||

| SAE 1010 | 0.08-0.13 | 0.30-0.60 | 0.35 Max | 0.030 Max | 0.030 Max | |||||

| SAE 1015 | 0.12-0.18 | 0.30-0.60 | 0.35 Max | 0.030 Max | 0.030 Max | |||||

| SAE 1018 | 0.15-0.20 | 0.60-0.90 | 0.35 Max | 0.030 Max | 0.030 Max | |||||

| SAE1022 | 0.17-.023 | 0.60-0.90 | 0.35 Max | 0.030 Max | 0.030 Max | |||||

| SAE 10B21 | 0.18-0.23 | 0.80-1.20 | 0.35 Max | 0.20 Max | 0.030 Max | 0.030 Max | 0.0005-0.0035 | |||

| SAE 15B25 | 0.23-0.28 | 0.90-1.30 | 0.35 Max | 0.20 Max | 0.030 Max | 0.030 Max | 0.0005-0.0035 | |||

| SAE 15B41 | 0.36-0.44 | 1.35-1.65 | 0.15-0.30 | 0.030 Max | 0.030 Max | 0.0005-0.0035 | ||||

| 19MnB4 | 0.20-0.26 | 0.80-1.10 | 0.30 Max | 0.30-0.40 Max | 0.050 Max | 0.40 Max | 0.0005-0.0035 | |||

| C-35 | 0.30-0.40 | 0.50-0.80 | 0.15-0.35 | 0.050 Max | 0.040 Max | |||||

| HC 46-50 | 0.46-0.50 | 0.50-0.80 | 0.15-0.35 | 0.035 Max | 0.035 Max | |||||

| HC51-55 | 0.51-0.55 | 0.50-0.80 | 0.15-0.35 | 0.035 Max | 0.035 Max | |||||

| HC 56-60 | 0.56-0.60 | 0.50-0.80 | 0.15-0.35 | 0.035 Max | 0.035 Max | |||||

| HC 61-65 | 0.61-0.65 | 0.50-0.80 | 0.15-0.35 | 0.035 Max | 0.035 Max | |||||

| HC 66-70 | 0.66-0.70 | 0.50-0.80 | 0.15-0.35 | 0.035 Max | 0.035 Max | |||||

| HC 71-75 | 0.71-0.75 | 0.50-0.80 | 0.15-0.35 | 0.035 Max | 0.035 Max | |||||

| HC 76-80 | 0.76-0.80 | 0.50-0.80 | 0.15-0.35 | 0.035 Max | 0.035 Max | |||||

| SAE 1541 | 0.36-0.44 | 1.35-1.65 | 0.15-0.30 | 0.030 Max | 0.030 Max | |||||

| SAE 4140 | 0.38-0.43 | 0.75-1.00 | 0.20-0.35 | 0.80-1.10 | 0.040 Max | 0.040 Max | 0.15-0.25 | |||

| SAE-8620 | 0.18-0.23 | 0.70-0.90 | 0.20-0.35 | 0.40-0.60 | 0.040 Max. | 0.040 Max. | 0.40-0.70 | 0.15-0.25 | ||

| SCM-420 | 0.18-0.23 | 0.60-0.85 | 0.15-0.35 | 0.90-1.20 | 0.030 Max. | 0.030 Max. | 0.15-0.30 | |||

| EN-42 | 0.70-0.85 | 0.55-0.75 | 0.10-0.40 | 0.050 Max. | 0.050 Max. | |||||

| EN-19 | 0.35-0.45 | 0.50-0.80 | 0.10-0.35 | 0.90-1.50 | 0.050 Max | 0.050 Max. | 0.20-0.40 | |||

| EN-31 | 0.90-1.20 | 0.30-0.75 | 0.10-0.35 | 1.00-1.60 | 0.050 Max | 0.050 Max | ||||

| EN 8D | 0.40-0.45 | 0.70-0.90 | 0.05-0.35 | 0.060 Max | 0.060 Max | |||||

Though every care has been taken for typographical errors, please refer classified standards for any clarification.